New Delhi: GE has successfully proved operation of a megawatt-class and multi-kilovolt hybrid-electric propulsion system at 45,000ft, meaning the research programme can move on to flight-testing in the coming years.

The tests of the high-power, high-voltage system – including electric generators, power converters, power transmission and power control systems – demonstrated performance of the components in a replicated flight environment, simulating single-aisle commercial aircraft operations.

The testing was completed earlier this year at NASA’s Electric Aircraft Testbed (NEAT) facility in Ohio, but only announced at the Farnborough Airshow on July 19.

Describing this as a key milestone and a world-first achievement, Mohammed Ali, Vice President and General Manager of engineering for GE Aerospace said at the ongoing Farnborough Airshow that the company was “making aviation history by developing the technology to help make hybrid-electric flight possible for everyday commercial air travel.”

Elaborating further on this, Ali said “GE is proud to be a longstanding partner with NASA for development of new aviation technologies. Together, we just passed a key milestone by successfully concluding the world’s first test of a high-power, high-voltage hybrid-electric system at altitude conditions.”

GE describes the system as a “building block” for future propulsion programmes, with entry into service forecast in the mid-2030s.

“GE is proud to be a longstanding partner with NASA for development of new aviation technologies. Together, we just passed a key milestone by successfully concluding the world’s first test of a high power, high voltage hybrid electric system at altitude conditions. We appreciate the collaboration to make this possible. This is one of many milestones in our journey with NASA towards demonstrating a hybrid electric aircraft engine system for a more sustainable future of flight,” Ali said.

The NEAT facility where testing took place is a NASA reconfigurable testbed used to design, develop, assemble and test electric aircraft power systems.

“NASA’s unique NEAT facility is the only testing location capable of simultaneously providing both high-electric power and high-altitude conditions in an area large enough to fit an entire electric power train, and we are proud to see this test with GE come to a successful conclusion. This facility has become highly sought after by GE and others across the aviation community, and it is critical to supporting the agency’s goal of developing technologies that will enable and support future climate change adaptation initiatives,” said Bob Pearce, associate administrator for NASA’s Aeronautics Mission Research Directorate.

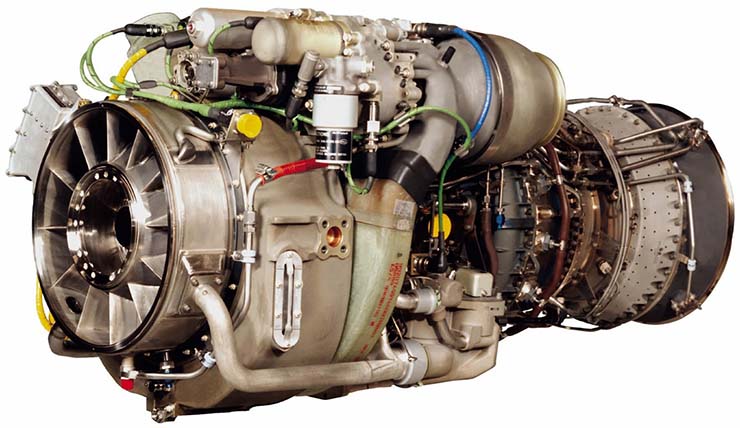

Future tests will be conducted as part of NASA’s Electrified Powertrain Flight Demonstration (EPFD) project, which was launched by the agency in September 2021, using a hybrid-electric system connected to GE’s CT7 turboprop engines.

A CT7-powered Saab 340B will be used for flights tests of the hybrid-electric system later this decade. Boeing is partnered with GE to support the flight tests for the EPFD, providing the aircraft, modifications, integration and flight-testing services.

Ali spoke of the initiative with NASA saying that it had become the first to successfully test high-power hybrid electric aircraft engine components at high-altitude conditions. This development will help make hybrid electric flight a reality and it should have a noticeable impact on the carbon emissions associated with flying. The tests for the same proved that the development is altitude ready, the next step would be to prove that they are flight ready. GE further plans to partner with Boeing subsidiary Aurora Flight Sciences to test the system in the air on a Saab 340B plane using GE’s CT7 engines.

In February, Airbus and CFM international – a 50-50 joint company between GE and Safran Aircraft Engines had announced plans to collaborate on tests of an aircraft engine fuelled by hydrogen. At the Farnborough Air show, Airbus said it would join the cause along with CFM by participating in the RISE Program, launched in 2021. Further in the second half of the decade, the aircraft manufacturer will partner with CFM to carry out a flight test demonstrator program on an Airbus A380 to validate the open-fan engine architecture.

Alex Hills, a test hardware engineer at GE Aviation with a passion for 3D printing along with Chris Lorence, chief engineer and general manager for GE Aviation, explained the open-rotor concept of the RISE project.

Lorence, who was preparing for an industry sustainability conference in Europe was looking for a prop that would easily communicate to his listeners what the advanced open fan was. Hills’s passion for 3d printing helped do the job and at the conference, the model turned out to be a great way to let people see what GE meant when they talk about these technologies.

NASA along with partners like GE are doing ground-breaking work on more sustainable aviation.

This is being done with the intent of creating technologies that show a promising future in terms of efficiency and sustainment. As the aviation industry strives for net-zero CO2 emissions from commercial flight by 2050, NASA continues to pave the way by actively partnering with industry leaders like GE to develop new types of sustainable aviation fuel (SAF). Another pioneering body in attaining this goal is the Glenn Research Centre with their electrified aircraft propulsion (EAP) research. It’s a major force in the industry’s mission to decarbonize air travel and in NASA’s Electrified Power train Flight Demonstration (EPFD) project, a five-year effort announced in 2021 to rapidly mature integrated, megawatt-class EAP technologies.

GE90 and the GEnx engines were displayed at the airshow along with the LEAP engine, developed by CFM which is the fastest-selling engine in aviation history. It showed GE’s preparation to set the airshow’s agenda of innovation with its Revolutionary Innovation for Sustainable Engines Project, with the goal of creating engines that use 20% less fuel and produce 20% fewer CO2 emissions than the most efficient jet engines built today along with the so-called open-fan architecture.

Meanwhile, GE engineer Christine Andrews and her team are collaborating with NASA and Boeing to develop a technology demonstration of a hybrid electric engine for commercial aircraft.