New Delhi: PTC Industries Limited and French multinational company Safran Aircraft Engines on November 30 inked a Memorandum of Understanding (MoU) to bridge defence and civil aerospace sectors requirements in India.

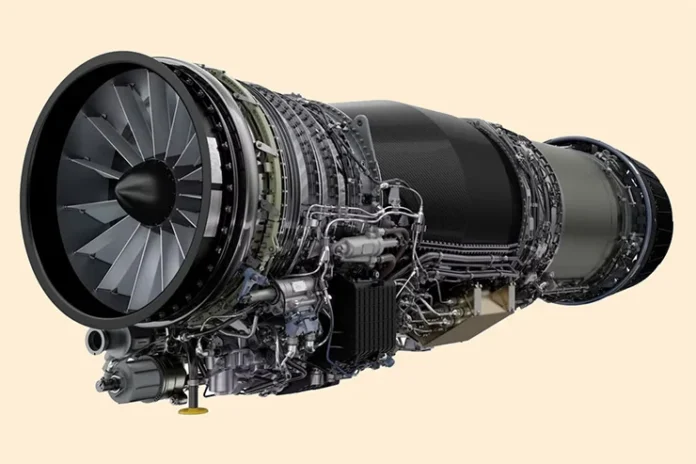

PTC manufactures high-quality, high-precision metal components for various critical and super-critical applications. Safran is engaged in design, development, manufacturing, and maintenance of civil and military aircraft engines as well as other aerospace and defence-related equipment.

Under the MoU, the organisations will identify and develop opportunities for cooperation and partnership on various fronts to meet the anticipated requirements of the military and aerospace sectors.

“Through this MoU, PTC and SAE shall discuss and assess the business opportunities for a broader scope of collaboration in the design, development, manufacture, maintenance, training, and upgrade of high-thrust aero engines,” the company said in a statement.

As part of the MoU, the two organisations will explore manufacturing and supply of Titanium and Super Alloy castings and components by PTC (through its wholly owned subsidiary, Aerolloy Technologies) for the LEAP engines, for civil aircraft engine applications. Further, the companies will also explore manufacturing and supply of Titanium and super alloy castings and components by PTC for the M88 engines, for military aircraft engine applications.

The two firms will also work on any other business opportunities that may be “mutually agreed upon, potentially in the field of military and/or civil aircraft engines”, the company said. The aircraft engine market is expected to grow from $54.7 billion in 2022 to $112.6 billion in 2029 at a CAGR of approximately 11 per cent. India is expected to have demand for over 2,200 civil aircraft in the next two decades, the company said.

“In India, over the next two decades, by some estimates, it is expected that there will be a requirement for 2,700 turbine engines for fighter aircraft, including those for replacement and trainers, and over 5,000 helicopter engines of various classes,” it added.

Manufacturing of critical cast components, in Titanium and Super Alloys, used in aircraft engines, is limited to very few companies and countries in the world currently and both organisations shall work together to address this gap, the company said.