Hyderabad: India witnessed a major development in its aviation and defence landscape as Safran expanded its industrial footprint through new maintenance and manufacturing initiatives. The French aerospace group strengthened its collaboration with Indian partners while advancing the goals of the Make in India programme. The expansion is set to enhance engine servicing capacity and deepen local defence manufacturing.

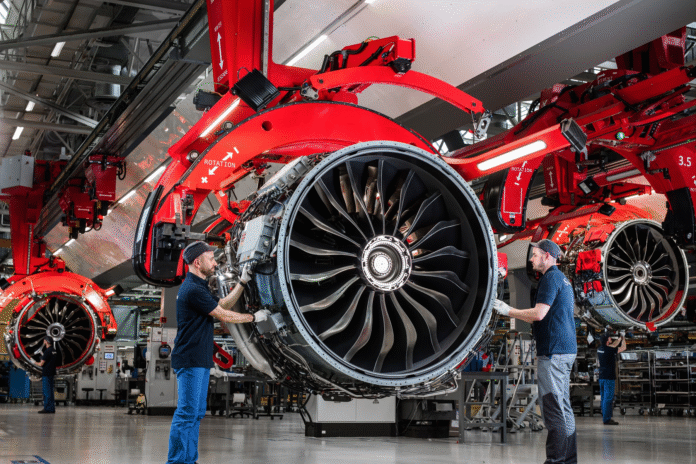

Safran’s newly inaugurated LEAP engine maintenance, repair, and overhaul centre is located here. It will support aircraft powered by engines from CFM International, which services a large share of India’s commercial fleet. The facility is expected to reduce overseas maintenance requirements and streamline turnaround times for airlines such as IndiGo (6E) and Air India (AI). Safran’s new facilities will support civil and military aviation programmes and offer long-term value to airlines operating Airbus and Boeing aircraft.

The projects were launched in partnership with various Indian organisations and include plans to scale local sourcing, increase production capabilities, and boost employment across multiple cities. The company has also expanded its electronics and avionics manufacturing base in Bengaluru. These additions mark a significant phase of industrial growth and strengthen the aerospace supply chain.

Safran plans to triple its annual revenue from Indian operations by the end of the decade, demonstrating long-term confidence in the local aviation sector. Safran’s expansion also includes military-focused initiatives that support India’s defence modernisation programme. A new maintenance facility for the M88 engine, which powers the Dassault Rafale fleet, will be established to improve readiness and reduce dependence on foreign repair hubs.

In addition to engine work, Safran and Bharat Electronics Limited will jointly manufacture air-to-surface weapons designed for use on both imported and domestically produced fighter aircraft. This agreement aligns with India’s aim to develop a more self-sustaining defence ecosystem. The company continues to collaborate with Hindustan Aeronautics Limited on the production of forged and machined components for commercial and military engine platforms.

These investments are structured to support rapid growth in India’s civil aviation market, which continues to add single-aisle aircraft at a steady pace. Localising engine servicing improves cost efficiency and supports airline expansion plans. On the defence side, increased manufacturing capacity enhances operational flexibility and strengthens domestic capabilities in high-precision engineering. The combined effect positions India as an emerging aerospace hub with long-term potential.

Safran’s sustained commitment signals both strategic partnership and industrial confidence, reinforcing India’s role in global aviation networks. Safran’s latest expansion across Hyderabad and Bengaluru marks a pivotal step in strengthening India’s aviation and defence sectors.

The new MRO facilities, manufacturing partnerships, and long-term localisation plans are expected to deliver significant benefits for airlines and the armed forces. These developments support Make in India goals while building a stronger and more independent aerospace ecosystem.