Following “tareekh pe tareekh,” Hindustan Aeronautics Limited (HAL) announced on March 26 that it has finally received the first of 99 F404 engines ordered for the Tejas Light Combat Aircraft Mk 1A fighter jet from GE Aerospace of the US.

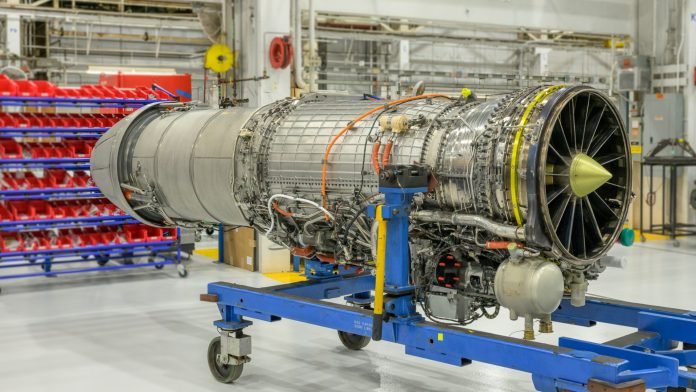

The performance and dependability of the F404 engine family are well-known. The McDonnell Douglas F/A-18 Hornet fighter aircraft was the primary focus of the engine’s development. It is a member of a family of turbofan engines that have been widely used in various military aircraft, such as the Lockheed F-117 Nighthawk, Northrop F-20 Tigershark, Boeing T-7A Red Hawk, TAI Hürjet, HAL Tejas, ST Aerospace A-4SU Super Skyhawk, Indian LCA, and the KAI T-50. The engine was built in response to previous competitive losses in fighter engine contracts. Initially, the Swedish JAS 39 Gripen also used the Volvo RM12, a license-built variant of the General Electric F404 engine.

The versatile engine has also been used in experimental designs such as the Scaled Composites Model 400, Dassault Rafale A(prototype), Grumman X-29, Rockwell-MBB X-31, Boeing Phantom Ray, and Boeing X-45C.

The engines are anticipated to be manufactured under license by TUSAŞ Engine Industries (TEI) in Turkey, which will manage assembly, inspection, testing, and maintenance for both domestic and export customers. The Swedes stopped producing them in 2011, while South Korea is still actively involved in their production.

The F404-GE-IN20 engines are anticipated to be manufactured under license by TUSAŞ Engine Industries (TEI) in Turkey, which will manage assembly, inspection, testing, and maintenance for both domestic and export customers

The Variant for India

The F404-GE-IN20 is the particular version for the Tejas Mk 1A currently being supplied; it has been modified to satisfy the requirements of the Indian Air Force (IAF). Several distinctive characteristics set the F404-GE-IN20 apart from the common versions used in other countries. One of the main distinctions is its thrust rating, which is tuned to generate roughly 84 kN with an afterburner. This thrust level ensures that India’s HAL Tejas Mk1A fighter aircraft offers dependable power for challenging missions by being specifically designed to fulfill its performance criteria.

The F404-GE-IN20 incorporates modern materials and technologies, particularly in its hot section components. These improvements increase the engine’s robustness and dependability, enabling it to function well in India’s varied climate, which includes high humidity and temperatures. Such adjustments are essential to maintain consistent performance in the various operating conditions that the Indian Air Force encounters.

The Full Authority Digital Engine Control (FADEC) system is another important component of the Indian version. Compared to previous models without FADEC technology, this sophisticated digital control system offers accurate engine performance management, improving efficiency, responsiveness, and reliability. Additionally, the FADEC system makes troubleshooting and maintenance easier, which makes it easier for operators to utilise.

Furthermore, the F404-GE-IN20 has been specially designed to tackle issues with performance deterioration in hot conditions. Because of this modification, the engine will run effectively even in harsh environments, which are typical in many parts of India. Because of these changes, it is ideal for India’s operational situations.

The Full Authority Digital Engine Control (FADEC) system is another important component of the Indian version. Compared to previous models without FADEC technology, this sophisticated digital control system offers accurate engine performance management, improving efficiency, responsiveness, and reliability

The HAL Tejas Mk1A fighter aircraft and the F404-GE-IN20 have been meticulously developed to work together smoothly. This kind of integration improves overall mission capabilities and guarantees compatibility with the aircraft’s equipment. The engine’s modification reflects India’s emphasis on developing its own defense capabilities while utilising proven technologies from international partners like General Electric Aerospace.

Advantages of the Indian Version

Compared to regular F404 models, the F404-GE-IN20 engine type has several changes that have improved its fuel efficiency and maintenance schedules.

Using modern combustion technologies and materials is one of the main ways to reduce fuel usage. The IN20 version maximises airflow and combustion efficiency with its single-crystal turbine blades and high-flow fan. With an afterburner, these improvements enable lower fuel burn rates while preserving the engine’s thrust output of about 19,000 lbf (84 kN). FADEC systems make sure that fuel is managed correctly, which improves throttle response and cuts down on fuel use that is not necessary during transient operations. When compared to older F404 models that do not have such sophisticated control systems, this feature helps to improve fuel efficiency.

Thanks to revised blade designs and materials that reduce vulnerability to debris ingestion, the IN20 model also has better resistance to foreign object damage. This enhancement lessens damage-induced fuel inefficiencies and helps maintain performance levels. GE Aerospace’s focus on improving current features suggests only small improvements over the F404, which has an SFC of about 0.81 lb (0.37 kg)/(lbfh) for military thrust and 1.74 lb (0.79 kg)/(lbfh) with the afterburner. The IN20’s specific fuel consumption (SFC) numbers are not given, though.

Thanks to revised blade designs and materials that reduce vulnerability to debris ingestion, the IN20 model also has better resistance to foreign object damage. This enhancement lessens damage-induced fuel inefficiencies and helps maintain performance levels

The F404-GE-IN20 requires less maintenance and has a longer lifespan since it is made up of innovative hot-section materials including ceramic matrix composites and has better cooling systems that lower thermal stress. Longer overhaul intervals follow from this; accelerated mission testing has proven the engine can run the equivalent of 1,000 flying hours without showing any major issues. The IN20 model also includes the In-Flight Engine Condition Monitoring System (IECMS), a predictive maintenance system that monitors component wear in real time. In contrast to previous iterations that depended on less advanced monitoring methods, this system enables proactive maintenance and lowers the possibility of unplanned repairs.

Additionally, GE Aerospace’s use of the FLIGHT DECK lean manufacturing method during the IN20’s manufacture has shortened maintenance turnaround times and increased part availability. Faster module replacements and FADEC software updates are made possible by the construction of an intermediate-level maintenance facility at HAL’s Engine Division in India, which further reduces downtime.

The Indian Air Force is expected to save between 15 and 20 percent on operating expenses compared to previous engines because of the combination of increased fuel efficiency and reduced maintenance requirements for the F404-GE-IN20. Additionally, the Tejas Mk1A fighter aircraft’s fleet availability is increased due to speedier readiness brought about by predictive maintenance and local MRO infrastructure

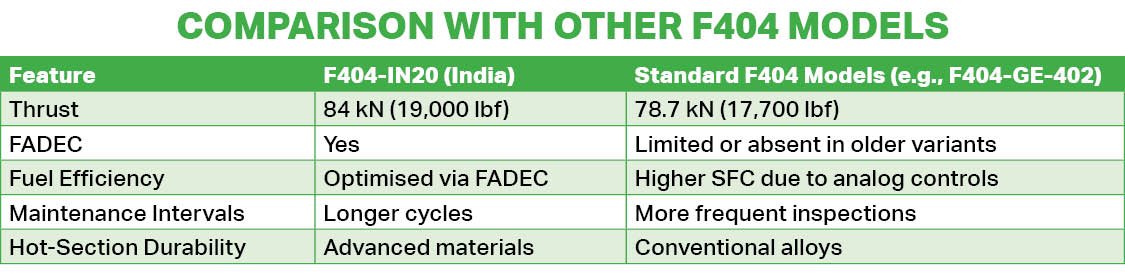

There are several differences between the F404-GE-IN20 and other common F404 variants, such as the F404-GE-402. Standard versions provide a thrust of 78.7 kN (17,700 lbf), whereas the IN20 variation generates 84 kN (19,900 lbf). FADEC increases the operational efficiency of the IN20, while older models sometimes lack digital control systems. Additionally, because older versions rely on analog controls, the IN20’s increased fuel efficiency results in greater specific fuel consumption (SFC). Standard versions need more frequent inspections, but the IN20’s sophisticated materials and design characteristics allow for longer maintenance intervals.

These changes demonstrate a strategic balance between enhancing performance and ensuring the long-term viability of India’s fighter fleet. The Indian Air Force is expected to save between 15 and 20 percent on operating expenses compared to previous engines because of the combination of increased fuel efficiency and reduced maintenance requirements. Additionally, the Tejas Mk1A fighter aircraft’s fleet availability is increased due to speedier readiness brought about by predictive maintenance and local MRO infrastructure.

The writer is the Publisher of Frontier India and the author of the book Foxtrot to Arihant: The Story of Indian Navy’s Submarine Arm.